|

|

|

Note: These instructions are for the older version of the Bucky skull. The ones currently being sold will have a "Made In China" sticker on the back of the head. Click here for insturctions on the newer skulls. |

|

|

| Click on the images to enlarge them |

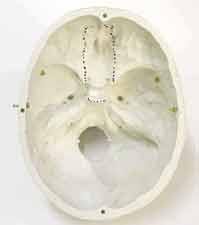

| We need to make a bracket that will allow us to mount a servo on the area marked by the dotted line. |  |

|

|

Install the jaw with cable ties, leaving enough slack for smooth jaw movement Remove the jaw springs and hardware. |

|

| If you were really good, the hole will line up perfectly, but more than likely, you'll have to "modify" the hole slightly to work with the connection between the servo and the jaw. |  |

|

Install the servo into the skull. I find that using just two of the four mounting holes is adequate. |

|

Cut the other end of the wire and do a pair of bends to fit the servo horn as shown. |

|

There are several ways to drive the servo. I've developed a very simplistic circuit to drive it with a audio source. Click here for details. If you've got questions on the above procedure or suggestions on how to improve it, please contact me. Happy Haunting |

| Halloween Home | last update 12/2008 |